Industry 5.0 and lead battery production

Thanks to CAM innovations you will be able to take advantage of many incentives

The two-year period 2024/25 will be two years to allow an epochal change for your company.

The United States and Europe have implemented important incentives for Industry 5.0

What is Industry 5.0:

Developing production systems based on renewable energy is one of the requirements that promotes Industry 5.0.

The objective is to reduce carbon emissions by 55% for 2030, the European Commission indicates in its paper that the industry must be sustainable to respect the limits of the Planet.

For this reason, it recommends developing circular processes that reuse and recycle natural resources, reduce waste and minimize environmental impact.

Incentives thanks to Industry 5.0:

Both in Europe and in the USA there are many incentives for those who invest in actions to reduce emissions and decarbonisation.

The major incentives are in:

USA: the IRA provides more than US$270 billion in climate- and clean energy-related incentives, including more than US$40 billion in tax credits to expand manufacturing of EVs, batteries, and numerous other types of clean energy technologies.

Italy: announced with 6.36 billion euros, replaces the 4.0 plan and integrates it with the three key concepts of sustainability, centrality of the person and resilience.

Incentives exist in many countries.

If you want more information I recommend you read this Deloitte article (https://www2.deloitte.com/us/en/insights/industry/manufacturing/manufacturing-industry-outlook.html)

Problem of production costs and emissions:

Countries that purchase gas are subject to the vulnerability of the gas price (see how it went in 2021/2022), in addition to the fact that emissions of CO2 and other gases are increasingly higher.

In addition to this, there is lead in the blood of the workers, which leads to sanctions for the company and workers’ strikes for greater rights.

There is a solution?

Yes.

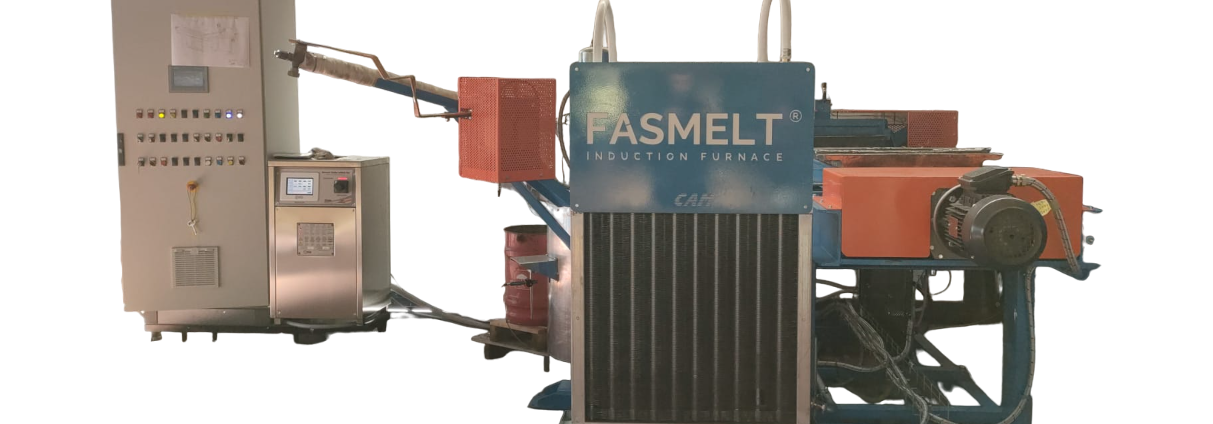

The solutions are there. Especially in the departments where lead melting takes place.

They are real solutions, which do not change the production process of lead-acid batteries.

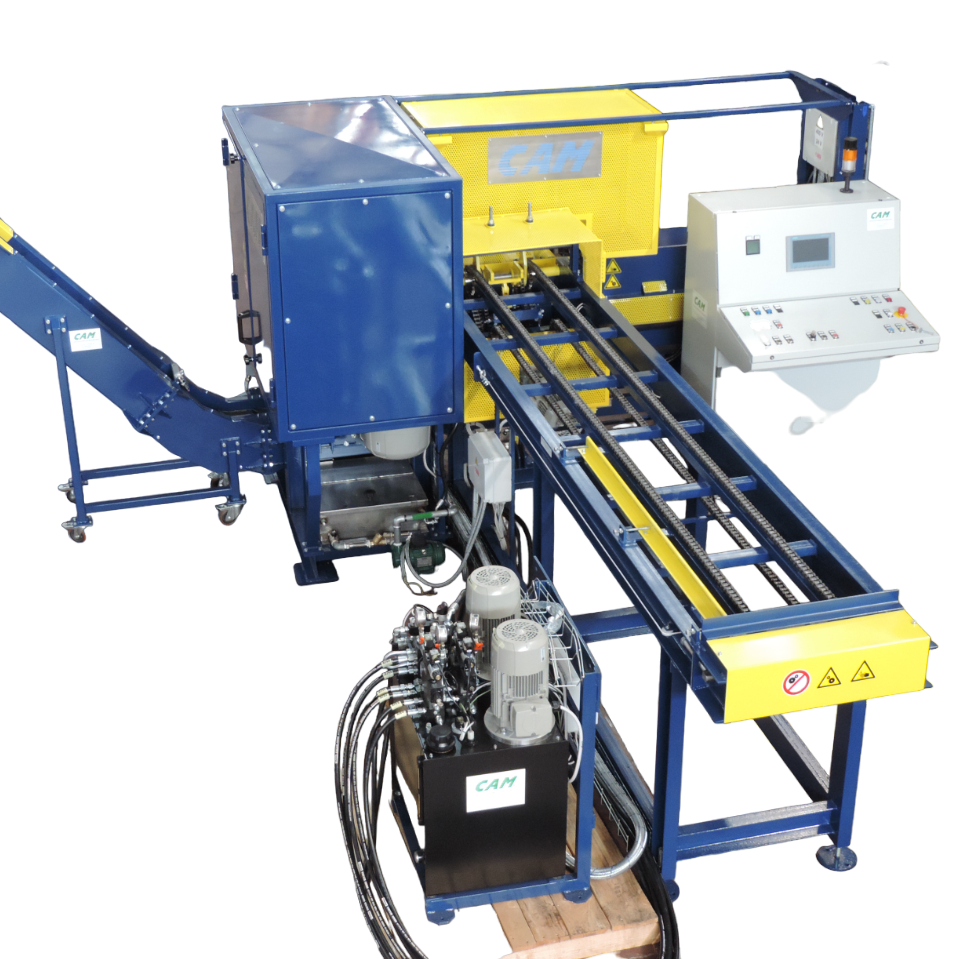

Lead shaver:

The shaver, thanks to LSS (lead shaving system) technology, is able to produce shaved cylinders for the production of lead oxide with mechanical milling.

Thanks to this process, no downstream processes are modified, which happens with other types of gas-free systems.