CARBON Flash Tunnel– Product Overview

The CAM CARBON FLASH TUNNEL is an automated system that has the purpose of hardening and drying battery plates after pasting.

DESCRIPTION OF THE PROCESS

During the lead acid battery manufacturing process, after paste mixing and pasting, the plates under go the flash drying process before the next step, which is the curing phase.

Because the temperature in the curing chambers is quite high and the process time is very long, the grids in the plates tend to soften, a condition which causes technical issues.

To prevent this, the grids need to be hardened in order to resist the subsequent technological processes because it has been found that plates that have been quickly pre-heated and dried acquire

a considerably higher Brinell hardness with respect to plates which have not undergone this process

DESCRIPTION OF THE OVEN

The uniqueness of the Carbon Flash with respect to similar machines is in the use of 2 fans which operate at the same time, directing the air flow from the burner’s combustion chamber to diffusers.

The upper and lower diffusers cover the entire length of the tunnel and are each connected to one of the two fans.

In case of faulty functioning of one of these fans, the tunnel can operate even with only one thanks to a forced air channeling system, with a slight modification of the speed of the belt.

Safety

A centrifugal fan is situated at the end of the tunnel, creating an adequate depression so that the air circulates continuously and consistently, so as to prevent the dangerous accumulation of gas which could cause dangerous explosions.

Furthermore, the tunnel is also equipped with a manual throttle valve.

Yield

The oven has a production capacity of 175 double expanded metal plates per minute calculated on the basis of plates having a thickness of 145mm.

(mass thickness may cause variations in the speed of production).

Heating system

The oven is heated by n. 1 modular duct burner, with a thermal capacity of 360.000 Kcal/h.

Because it is modular, gas is consumed only when needed.

Air circulation (14.000 m3/h max each) is assured by two 7 kW open propeller fans which by means of the diffusers direct it to the upper and lower surface of the plates.

Plate movement system

The plates are moved by a stainless steel mesh conveyor belt driven by a variable speed motor/gearbox activated by inverter.

The speed can vary up to 40m/min.

Belt tension is guaranteed by a mechanical tensioner with inverter with oscillating arms.

This prevents jolting movements of the belt, to avoid shifting of the position of the plates.

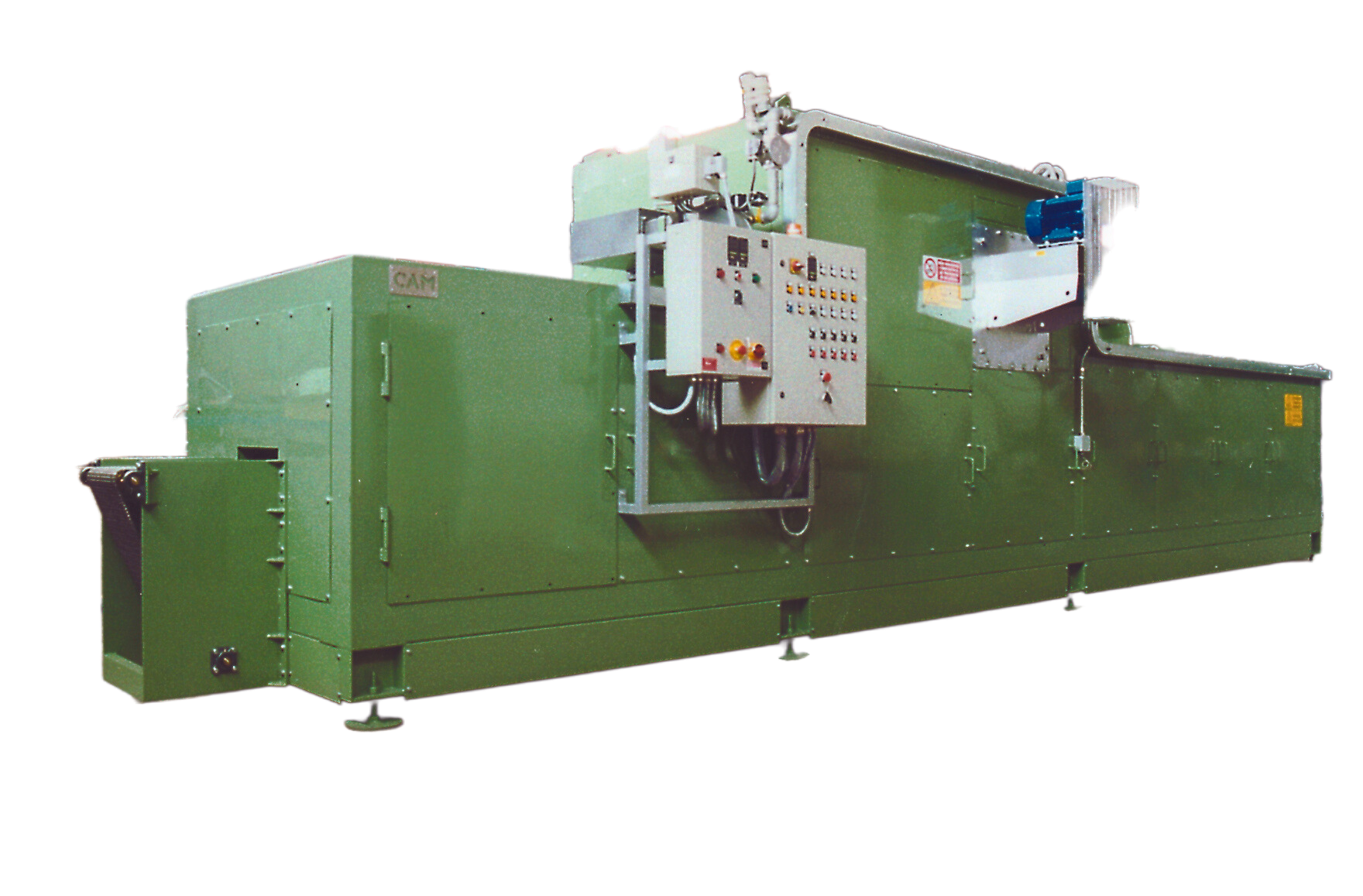

Heavy duty structure

The structure is sturdy and completely insulated, equipped with easily accessible inspection portals,

and easily disassembled panels to facilitate maintenance operations.

The footprint of the oven in terms of length is 10.250mm including motor head and return. The tunnel section is 9 meters long.

Process is controlled by means of strategically placed temperature probes and pressure gauges, interfaced with the easily accessible control cabinet which is located on one side of the oven.

The oven is equipped with a Siemens S7-1200 PLC interfaced with a touch operator’s panel on which it is possible to select all of the necessary process data.

ADVANTAGES

The CAM Carbon Flash oven is designed to harden plates thanks to the uniform diffusion of CO2 over the entire length of the conveyor, so as to create a uniform layer of carbonate on the treated plates.

Besides hardening the plates, this process facilitates penetration of steam during the curing process, thus optimizing results.

The process creates carbonate on all types of plates, and is particularly adapt for pasted plates without paper.

TECHNICAL DATA AND UTILITIES

| Electrical Power supply | 20 kW installed, 400 V, 50 Hz | |

| Throughput | 175 double plates/min | |

| Plate height with expanded strip grids | 145 mm | |

| Thermal capacity of n. 1 gas burner | 360.000 kcal/h | |

| Methane supply | 40 m3/h | |

| Methane pressure | < 100 mbar | |

| Minimum air exchange (external suction) | 6000 m3/h | |

| Total footprint | L3.780xW10.250xH2.650 [mm] | |

Product Layout:

If you want more information about it, please fill out this form:

CARBON Flah Tunnel Video

For privacy reasons YouTube needs your permission to be loaded. For more details, please see our Privacy Policy.

I Accept