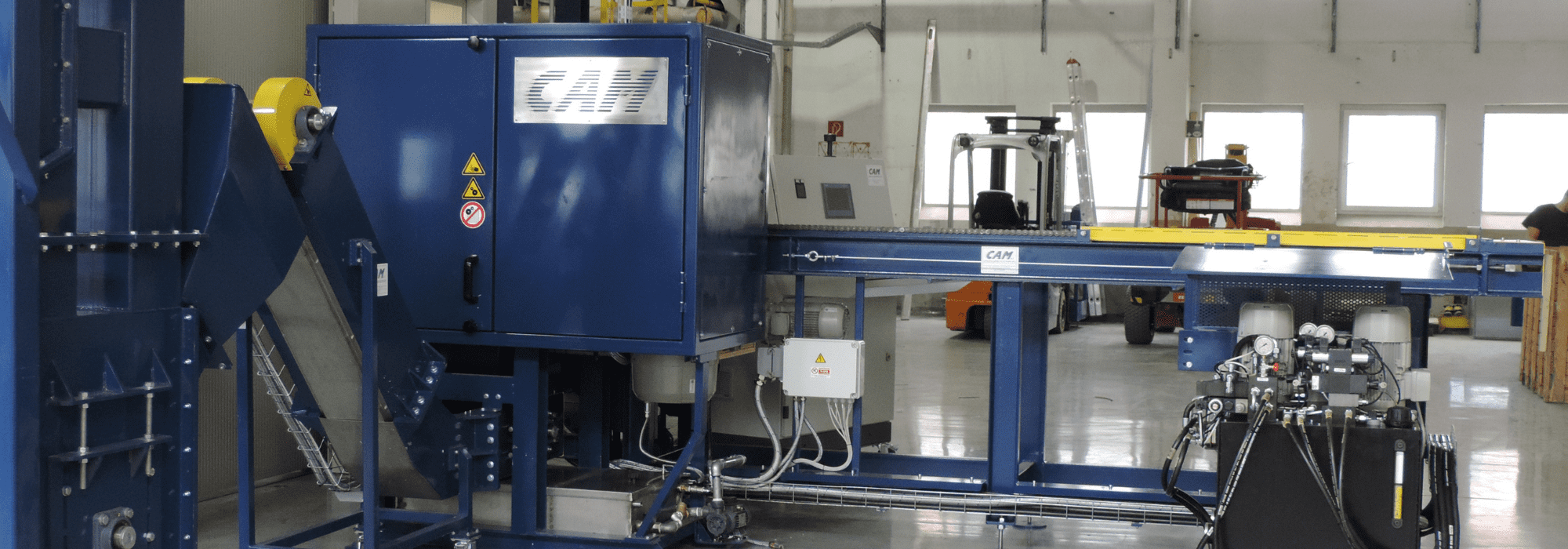

Clean production of lead cylinders thanks to LSS Technology (Lead Shaving System)

Thanks to the lead shaving system (LSS technology), today you can produce lead oxide without emissions and lead in the air.

Plus, you’ll have at least 652 MWh/year less consumption.

There are many reasons why you should use LSS Technology (Lead Shaving System) :

-

Production cost problem

-

Calculation of TCO (Total cost of ownership)

-

Problem of emissions

-

Problem of free lead emissions and the new European limits

As you can see, there are many reasons, but let’s start describing them one at a time.

1. Production cost problem

In 2022, manufacturing companies experienced significant cost increases resulting from rising energy costs.

In particular, the cost of gas has increased significantly.

This led to a reduction in profits with the same turnover, and worse still, many lead-acid battery companies made a loss.

Just consult the turnover and profits of many plants to verify this.

LSS Technology uses only electricity, which can be self-produced from renewable sources installed in the plant.

This allows you to be energy independent and not dependent on the price of gas.

Less 652 MWh of energy consumed for every million batteries produced.

This is the most important data.

2. Calculation of TCO (Total cost of ownership)

The purchase price of a production line is important, but it is also important to know all the hidden costs.

The purchase cost is what you see at the tip of the iceberg, the indirect costs are under water, you don’t see them, but you can calculate them.

I always talk about TCO (total cost of ownership). Among these indirect costs is the cost of energy consumption.

Energy consumption is the highest value you find in the TCO.

Luckily there are machines that save you a lot, which is why the purchase cost becomes irrelevant.

Thanks to LSS (Lead Shaving System) technology,

at least 652 MWh are saved x 1 million batteries produced in a year.

652 MWh, multiplied by the cost of your company’s energy, is the monetary result of the economic/annual savings.

With this energy saving,

the emission of 346 tons of CO2 is avoided